Blowers Refurbishment

If you would like to receive an approximate quotation to have your blower refurbished please email or call us on 01526 399711 at the office today.

The Service

Pole Star offers a comprehensive service for the Building Services Engineer, Maintenance Firms, Facilities Companies, Heating Contractors, Electrical Engineers etc. We refurbish direct drive and belt drive blowers in any quantity with quick deliveries. These are often alternatives to current competitor brands, or direct equivalents to old and obsolete models which are either no longer available, or expensive when purchased from other suppliers.

We offer both a standard turnaround which is generally 5-7 working days and we also offer an express service which is 1-2 working day turnaround. For larger volumes part shipments can be made or a whole shipment a few days later.

In many buildings as fan coils have been running for 20-30 years the bearings and motors start to fail and the moving part of the blower reaches the end of its life. When a blower starts to reach the end of its life many sites and engineers look at the options of refurbishing the units. In most situations the scrolls and wheels are in perfectly good condition and it is just the motor that has failed, as a result refurbishment is often a far cheaper and quicker option than manufacturing complete new units.

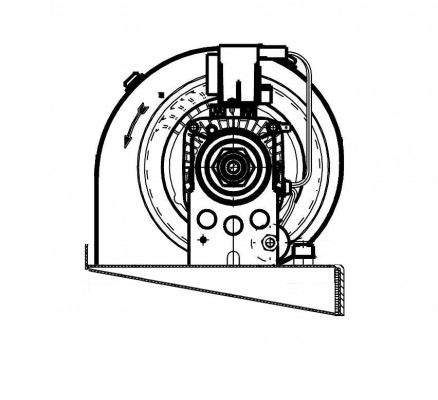

Blower Unit Styles belt drive

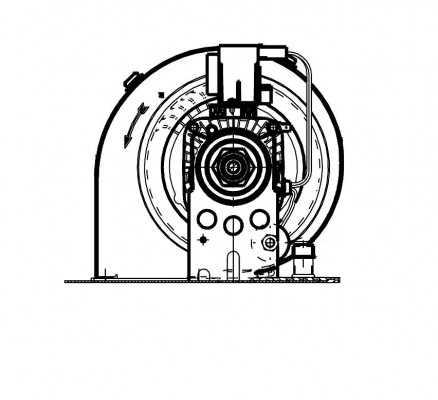

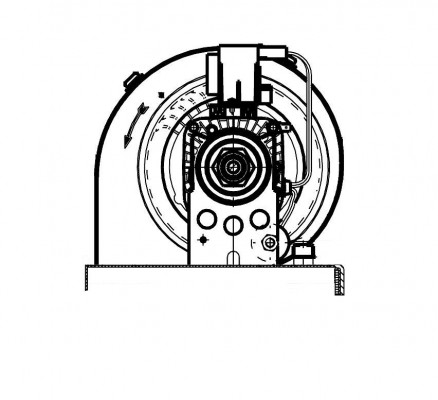

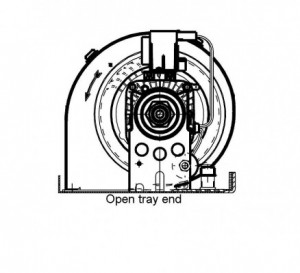

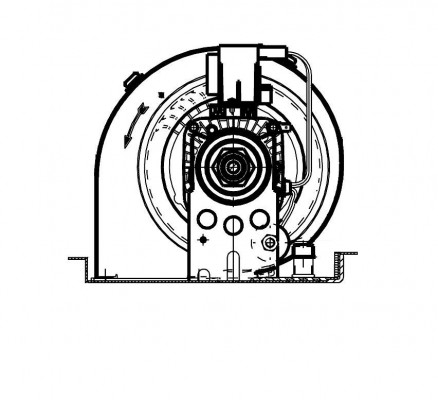

The range of blower units come in several shapes and sizes, the key differences are between a belt drive and a direct driven blower unit.

Like Russian dolls, blower units scale up in size form the smallest 7/5 all the way to the largest 18/18, we are able to service all of these sizes.

Facilities

With the onsite facilities we have our speciality is being able to manufacture new decks of any quantity to your specification. With the guillotine, lathe, milling machines, presses and bending equipment we are quickly and efficiently able to produce trays to most profiles to suit your needs, below are some examples of the most common tray profiles:

The Refurbishment Process

We receive a wide range of blowers from a vast array of applications; they all arrive to us in varying conditions. Some appear in pristine condition apart from a failed motor, whilst others requite a little more care and attention to bring them back to their original condition.

Here are some of the cleaning processes which we may use in order to refurbish the blower units:

Chemically dipped

We use an industrial cleaning chemical to dip the complete units in overnight, this helps “lift” the dirt, grime and grease which makes the next stage easier.

Pressure washing

Using an industrial pressure washer we spray down every deck. Again we use a cleaning fluid to clean trays, scrolls and wheels to remove any dirt that could hinder the performance whilst also making the deck more aesthetically appealing.

Scrubbing

If after the chemical dip and pressure wash some dirt remains we use our dip tray cleaner to scrub the units down. This is the final stage of cleaning.

Once cleaned the decks are dried off (at which point they can be re-sprayed if requested). They are then re-assembled complete with a new motor and new wheels/scrolls if they required replacing.

Profile A

Profile B

Profile C

Profile D

Profile E

THE REFURBISHMENT PROCESS

We receive a wide range of blowers from a vast array of applications; they all arrive to us in varying conditions. Some appear in pristine condition apart from a failed motor, whilst others requite a little more care and attention to bring them back to their original condition.

Here are some of the cleaning processes which we may use in order to refurbish the blower units:

CHEMICALLY DIPPED

We use an industrial cleaning chemical to dip the complete units in overnight, this helps “lift” the dirt, grime and grease which makes the next stage easier.

PRESSURE WASHING

Using an industrial pressure washer we spray down every deck. Again we use a cleaning fluid to clean trays, scrolls and wheels to remove any dirt that could hinder the performance whilst also making the deck more aesthetically appealing.

SCRUBBING

If after the chemical dip and pressure wash some dirt remains we use our dip tray cleaner to scrub the units down. This is the final stage of cleaning.

Once cleaned the decks are dried off (at which point they can be re-sprayed if requested). They are then re-assembled complete with a new motor and new wheels/scrolls if they required replacing.