Test Facilities

As a supplier of both large and small volume products we have a variety of technical facilities which enable us to test, report and evaluate both our own products and also other makes and models for where we are required to offer an equal performance model.

Some of the things we can test are:

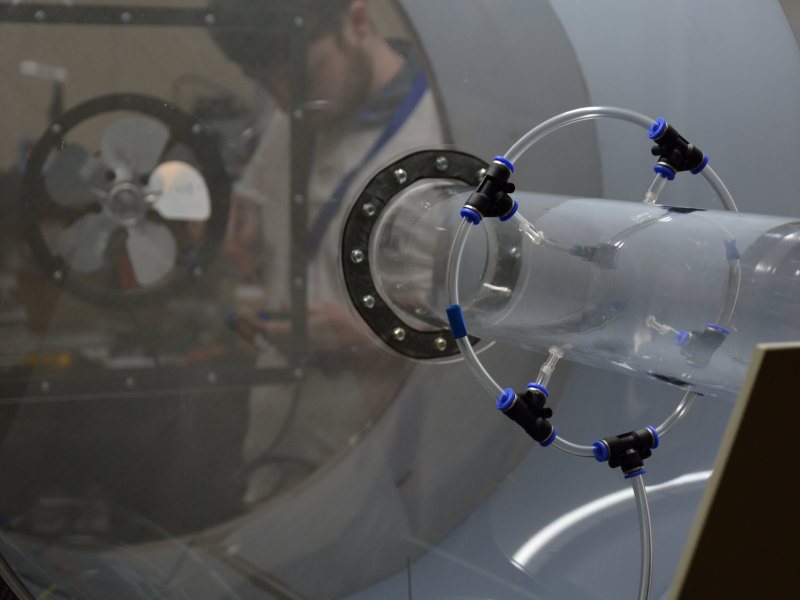

Aeraulic Test Chamber

In conjunction with the University of Lincoln and the School of Engineering department, we have produced a aerodynamic wind tunnel for fan performance measurement. For our equipment manufacturing customers it is crucial to the overall performance of the unit to get the correct airflow. Under the guidance of Dr. Jun Yao, a specialist in computational fluid dynamics and Dr. Rebecca Margetts, an expert in dynamics and vibration in 2016 we will complete our wind tunnel.

It complies with international standards set up by American National Standards Institute (ANSI).

Any installed fan will be monitored for electrical performance to give accurate power consumption, detailed flow readings based on pressure. With the advances in energy saving motors the need to state of the art test facilities has never been greater, having all this equipment in house enables us to respond quicker than any of our competitors who do not possess such equipment in the UK.

Click here for more information.

Dynamic Balancing

We have the ability to dynamically balance a fan unit or motor with our in house equipment. Excessive vibration in fans can cause unacceptable levels of noise, our dynamically balancing machine coupled with our vibration testing allows us to quickly solve problematic applications. A fan which is out-of-balance causes vibration as there is a displacement of mass from the centre line of the unit. Not only will this cause noise issues but it will also shorten the life span of the motor.

(images some to follow in other emails)

Voltage Testing

In our test labs we have various voltage test equipment which allow us to test original equipment motors voltage, amps and watts usage to enable us to offer suitable replacement motors. We can also use the equipment to stress test our own motors to evaluate their ability to cope with energy spikes.

Motor/Fan Fun Speed Testing

We have a tachometer which allows us to find a motor or fans running speed (RPM), when replacing old or obsolete motors this is invaluable when ensuring we offer a motor which is as close in performance to the original as possible.

Temperature Rise

By use of an infrared thermometer we are able to monitor the temperature rise of any given fan or motor. With bespoke units we are often asked to match motors to blades and wheels which are non standard sizes. It is a careful balancing act as the wrong match can lead to premature failure due to a motor overheating. With this equipment this is something which we can replicate and ensure the motors insulation class matches the likely heat rise.

We also are able to test small fans and motors inside a test oven to replicate high ambient temperatures or to accelerate a motors life span for test purposes.